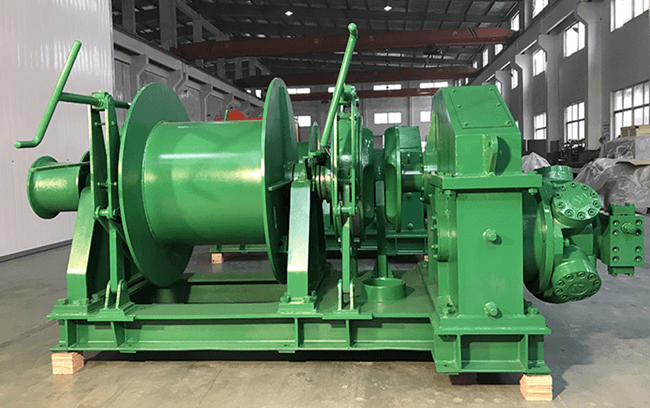

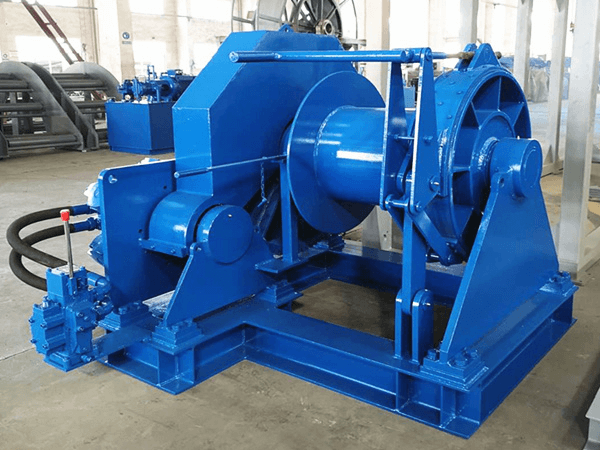

Hydraulic winches are widely used in marine engineering projects, engineering construction, water conservancy and hydropower engineering, forestry and fruit industry. In order not to harm the application and reduce the high efficiency, we must adjust the gap of the brake pads. The following will introduce to you how the equipment adjusts the gap of the brake pads:

1. As soon as the gear oil is hot, the lifting winch is slow due to the high temperature of the gear oil and the reduction in viscosity, that is, it becomes dilute. If the operating temperature is so high, it is recommended to change the refined oil, and oil viscosity is too weak.

2. Adjust and improve the clearance of brake pads

①In order to ensure the normal operation of the brake equipment, the device is equipped with a brake shoe damage limit switch and a butterfly-shaped spring switch.

②When everything is working normally, the gap between the brake shoe and the brake disc should be adjusted to 1mm when the control accuracy is very large. If the wear rate of the brake shoe reaches 1mm, the brake release gap becomes 2mm.

③At this time, if the position of the limit switch is damaged and the safety braking system is carried out, the brake shoe clearance must be adjusted at this time.

④ When adjusting the brake shoe gap, the working pressure oil is adjusted to a very large value, so that the brake is in a fully released state. At this time, now adjust the ring to promote the hydraulic cylinder, brake shoe and other parts to move forward until the brake shoe gap is 1mm.

⑤When lifting the winch braking system, you can use a micrometer to measure and check whether the disc brake clearance meets the requirements, and it is enough that it does not exceed 0.5.

The technology introduced by the hydraulic winch is used in raw material lifts or flat tractors in water conservancy and hydropower projects, forestry and fruit industry, mining, ports, etc. The brake pads of the equipment are very important for all equipment, so we must do a good job of its adjustment and maintenance, and in addition, we also need to carry out regular cleaning.